Bullet Proof Glass: Best Options for Ultimate Ballistic Resistance

When you need the ultimate level of protection for doors and windows against ballistic threats and high-powered projectiles, bullet proof glass is an incredible product designed to withstand the energy of a bullet when fired from different types of weapons.

But with so many options on the market, how do you decide which one is best for you? In this article, we’re talking all about bulletproof glass, from how much it costs and the types and thicknesses needed to withstand certain bullets and weaponry to stronger, more cost-efficient alternatives including acrylic panels and polycarbonate shield systems like BulletShield.

- What is Bullet Proof Glass?

- What is Bullet Proof Glass Made of?

- How is Bulletproof Glass Made?

- How Much Does Bullet Proof Glass Cost?

- Bullet Proof Glass vs. Normal Glass

- How Thick is Bulletproof Glass?

- Bullet Proof Window Film vs. BulletShield

What is Bullet Proof Glass?

Bulletproof glass, also known as ballistic glass, bullet-resistant glass or transparent armor, is a strong, typically reinforced transparent material manufactured to withstand penetration from projectiles, specifically bullets shot from a variety of firearms.

This also eliminates the threat of smash and grab attacks, because intruders simply can’t break bulletproof glass, even if they repeatedly smash the pane of glass with a brick, crowbar, or another weapon.

Is Bullet Proof Glass Really Bulletproof?

Contrary to how it sounds, bulletproof glass isn’t actually “bullet proof” – it’s bullet-resistant. Depending on the materials used during manufacturing and the thickness of the glazing, not all bullet-resistant windows or glass can withstand all caliber bullets.

What is Bullet Proof Glass Made of?

There are five different types of bulletproof glass on the market today. In this next section, we’ll take a look at all of the different types of bulletproof glass, from the original traditional laminated glass to some more innovative, cost-effective alternatives to help you decide which option best suits your needs.

Traditional Laminated Glass

The original bullet proof glass, laminated glass is made from layers of glass and resin. Brittle and heavy, this outdated glass is difficult to cut and drill, making it to challenging to incorporate into most anti-ballistics systems. However, fully customizable bulletproof glass security systems like BulletSheild can be retrofit to any existing glazing.

Insulated Ballistic Glass

Insulated ballistic glass is bullet-resistant security glazing that carries both a forced-entry and UL Level 1 bullet-resistant rating. They are easy to maintain and provide clear visibility and excellent light transmission, measuring only 1 – 1.125” thick. Insulated ballistic glass is good for both exterior and interior applications and is available in different transitional tints. Insulated ballistic glass also helps lower building cooling costs and enhance tenant comfort while providing security and protection from UL Level 1 ballistic attacks.

Acrylic Panels

Monolithic acrylic is the most common type of bulletproof “glass” on the market. Ranging in thicknesses from 1 ¼” to 1 ⅜”, acrylic is easy to drill, cut, route and slot, making it a malleable material for both flat and curved windows. Since monolithic acrylic passes light easily, visibility is not compromised by thickness. Although acrylic can be installed as either interior or exterior windows, acrylic does tend to crack and haze when exposed to UV light. This can impact the visual appearance of exterior acrylic windows over time.

Solid acrylic panels can be fabricated to UL-rated Level 1 or 2 bullet resistance. Level 1 systems can withstand three jacketed 9mm bullets, while Level 2 systems are able to stop three 38 caliber bullets.

Glass-Clad Polycarbonate (GCP)

Similar to laminated glass, glass-clad polycarbonate is crafted from layers of polyurethane-coated glass sandwiched between more polyurethane coating that’s capped with polycarbonate. GCP is available in bullet-resistance levels from Level 1 to Level 8. However, the higher the bullet resistance level, the thicker the glass-clad polycarbonate panel will be.

Similar to acrylic, GCP is difficult to incorporate into existing systems, can have poor light transmission, and can be susceptible to crazing.

BulletShield Ballistic Polycarbonate Shields

Since most bulletproof glass options require different levels of thickness to resist different caliber bullets, installing bulletproof glass can drastically change the appearance of the exterior of your building, and depending on the material, might also affect visibility.

Unlike some of the clunkier options on the market, BulletShield provides superior ballistic protection without compromising the integrity of your existing glass, changing the aesthetics of your building, or negatively impacting visibility. Even more, BulletShield is a complete security overglazing system, not just a polycarbonate panel.

BulletShield is fully customized and retrofit to your existing glazing frame using a vented extrusion using a “Super Bond” anchoring method that provides tensile, flex, and tear strength upon a ballistic attack. BulletShield is the perfect solution for schools, offices, government buildings and businesses seeking a cost-effective active shooter mitigation solution.

In fact, BulletShield has a variety of additional benefits that traditional bulletproof glass doesn’t, including:

- Street noise reduction by up to 40%

- Energy efficiency improvement of existing glass by more than 50%

- Smash-and-grab attack prevention

- Sacrificial film coating that withstands graffiti

How is Bulletproof Glass Made?

Bulletproof glass contains polyvinyl butyral plastic resin, glass, polyurethane, and ethylene-vinyl acetate. The most simple bulletproof glass contains one layer of PVB that is sandwiched between two layers of glass laminated with polyurethane and ethylene-vinyl acetate and bonded together at temperatures of 150° Celsius. Finally, incredible amounts of pressure are applied to the glass and PVR layers in an autoclave, melting the plastic to the glass to create a strong bond.

Since the bullet proof glass manufacturing process requires bonding layers of different types of materials together, it isn’t always flawless. Manufacturing issues often include:

- Layers not sticking together properly

- Layers containing trapped air

- Heat and pressure from the autoclave causing plastic distortion and visibility issues

In contrast, BulletShield is fabricated based on existing glazing conditions, threat levels and can work within budget restrictions. Depending on these factors, BulletShield systems may use exotic plastics, glass-clad shields, polycarbonates or a combination of these materials in addition to high-performance and superior quality installation materials.

How Much Does Bulletproof Glass Cost?

In many cases, the price of bulletproof glass doesn’t include the ballistic framing, which is equally as important as the glass system itself.

Not including bullet proof glass installation costs, prices can start from around $25 per square foot to over $100 per square foot, just for the sheet itself. How much bullet proof glass costs truly depends on the ballistic resistance and the material.

BulletShield vs. Bullet Proof Glass Price

BulletShield provides superior protection against ballistic attacks for a fraction of the price. Professional installed systems cost between $175 – $450 per square foot, depending on UL Level, location, project size, and the condition of the existing glazing. This is the price for the system with installation per square foot.

Bullet Proof Glass vs. Normal Glass

Normal glass that isn’t reinforced with security window film is easily broken by even the smallest amount of force. If you’re wondering how easily you can break bullet proof glass, the answer is not easily at all. Unlike normal glass, trying to break bullet proof glass with applied human force is next to impossible.

How Thick is Bulletproof Glass?

Typically made from a rigid and soft layer, bulletproof glass provides both rigidity and flexibility, allowing it to flex instead of shatter when subjected to a ballistic attack. Bullet proof glass ranges in thicknesses from ¾” – 3 ½”. The thickness directly relates to the type of bullet, number of bullets and distance from which those bullets are shot that the material can withstand the impact without failing.

Shooting Bullet Proof Glass

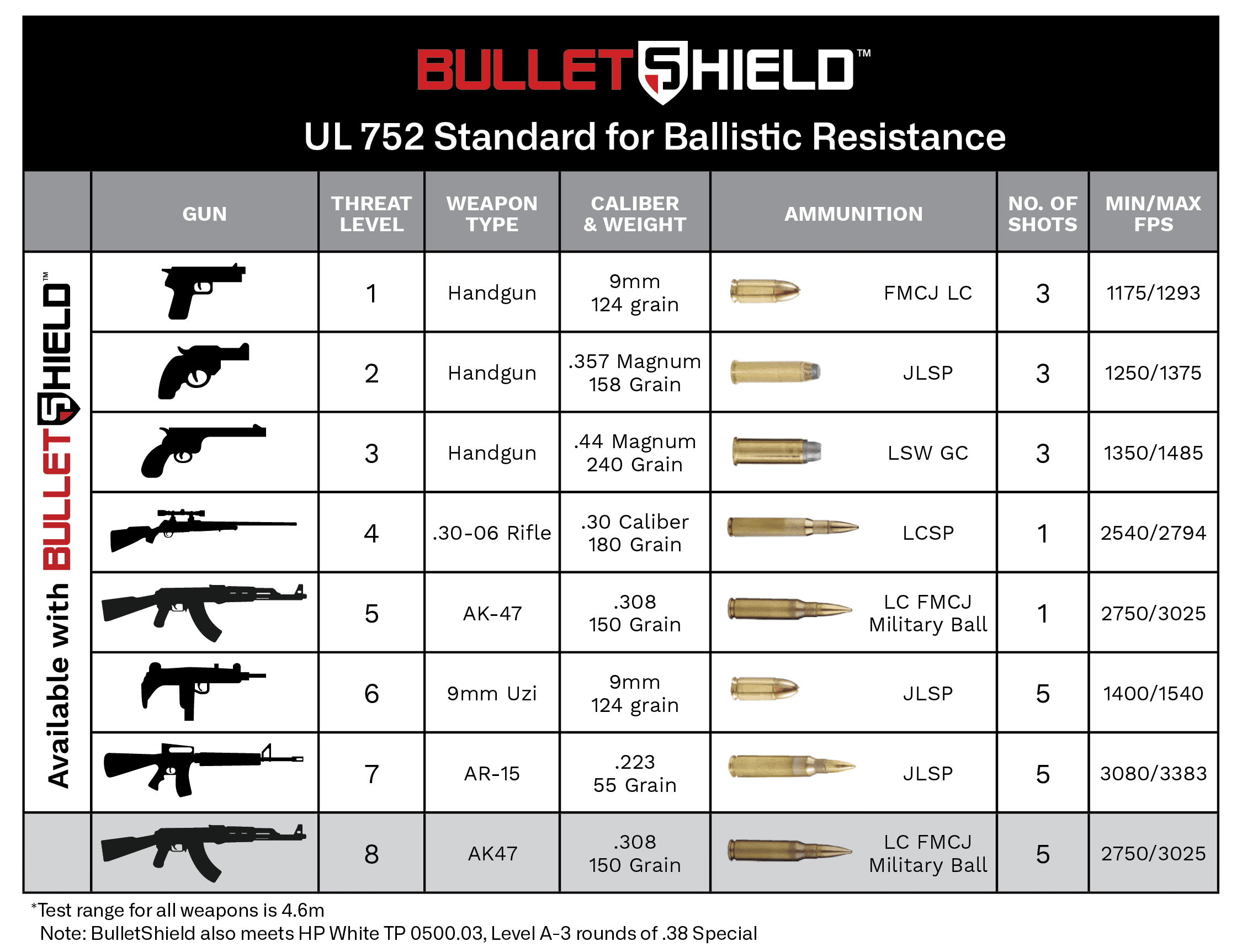

There are eight different ballistics ratings for bulletproof glass, also called UL ratings, as established by the Underwriter’s Laboratory. A non-profit organization and one of the few Nationally Recognized Testing Laboratories, the Underwriter’s Laboratory is authorized to perform safety testing by OSHA and developed the most widely accepted set of quality standards in the industry.

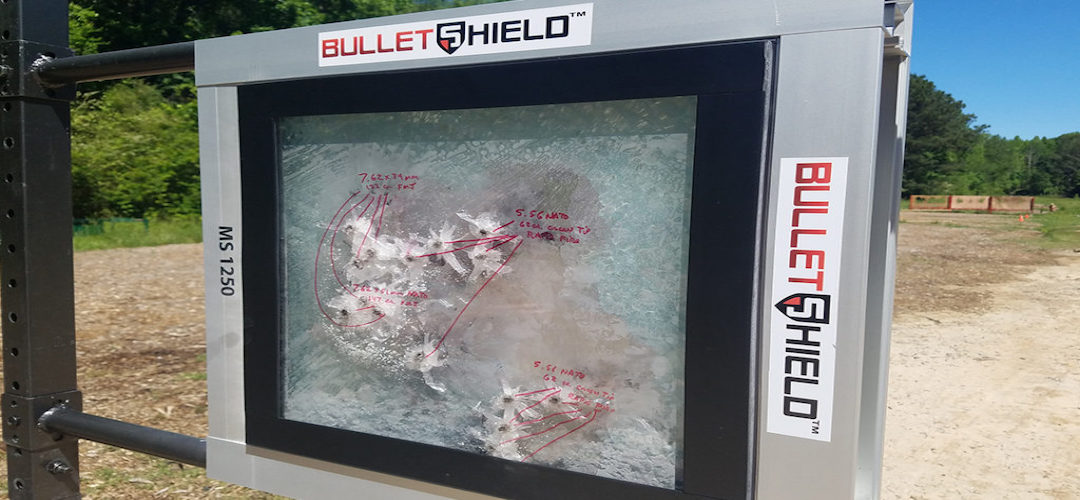

BulletShield is available in all eight levels of ballistic resistance per UL 752 standards, and depending on the threat level, can resist anything from a handgun to an AK-47.

Bullet Proof Window Film vs BulletShield

Currently, there is no true “bulletproof” window film on the market. Although some security window film options provide an excellent way to mitigate a ballistic threat by providing additional glass security, window film can’t actually stop a bullet.

When you need true protection against a ballistic attack that is cost-effective, customizable to your existing glazing, and that provides additional benefits without additional installations or products, BulletShield is a fantastic, all-inclusive option.